High Shear In-tank Mixing

Ampco’s in-tank mixers are used to hydrate, dissolve, homogenize, disperse and emulsify products consistently and efficiently covering a wide range of applications in food, chemical, and pharmaceutical industries. The multiple interchangeable stainless steel work heads are designed for 3A and CIP. The JET-shear can be used in open and closed tanks, drums or tote processing up to 5000 gallons / 22730 liters.

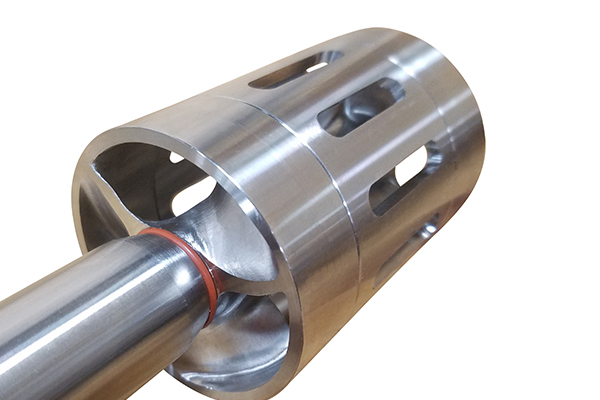

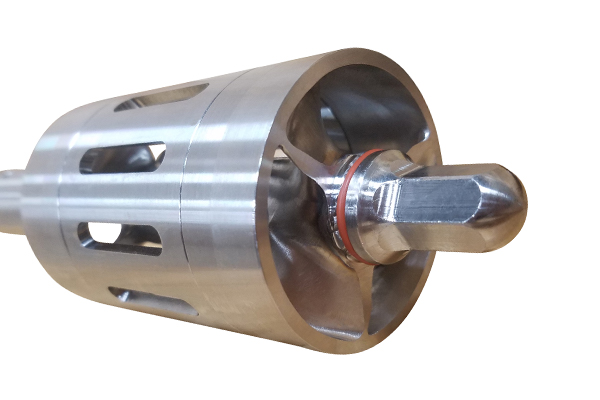

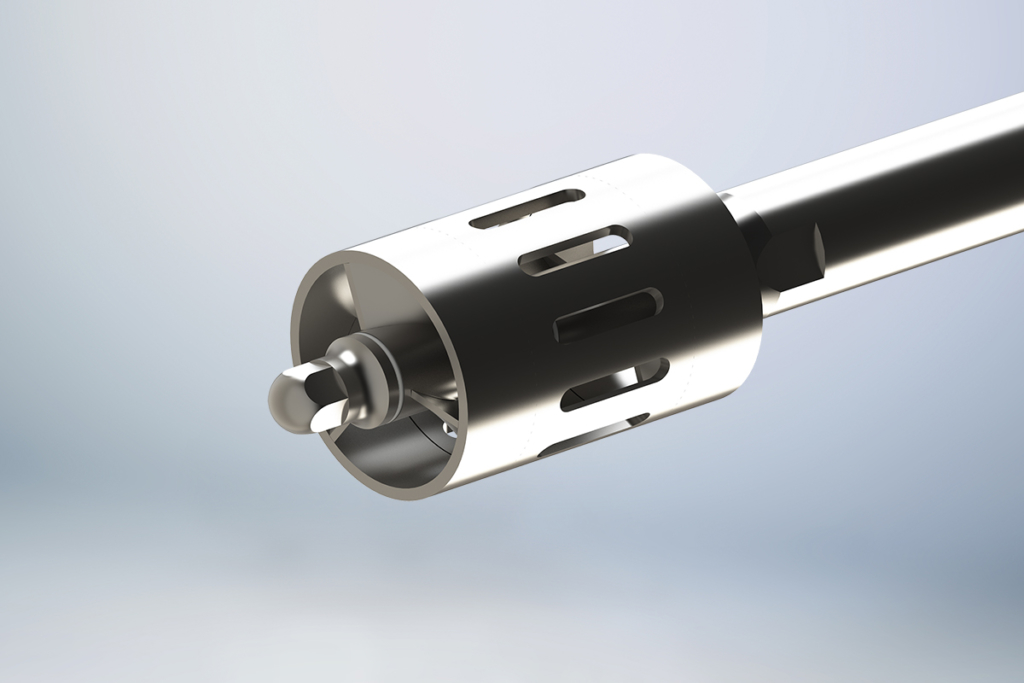

The specially designed propellers at the top and bottom of the work head draw material in and the centrifugal force moves the media out through the slots creating a mechanical shear. Reduce processing time, increase the quality and consistency of the blend, and increase throughput with the JET-shear.

Typical applications: agitate, de-agglomeration, disperse, dissolve, emulsify, eliminate fisheyes, homogenize, process acceleration and particle reduction. High quality heavy duty design, the JET-shear can handle the toughest applications. Custom shaft lengths, varying motor styles and mounting options are available. Contact Ampco Applied Products to discuss your specific application requirements.

JET-shear Features

- Emulsion to less than 10 microns

- Max volumes up to 5000 gallons / 22730 liters for self-mixing

- Stainless steel mixer shaft

- Multiple 316 stainless work head styles available

- Mixing heads can be interchanged

- Designed to 3A

- CIP-able

- Multiple mounting configurations

JET-shear Performance Overview

Models: 6 Shaft sizes / Models from 1-75 HP

Motor Speed: 1200-3600/RPM

Maximum shaft length: Max working shaft 96″/2440cm

Mounting options: custom stands and tank mounting options available for max flexibility

Bearing Housing: 304 Stainless

Pumps in Action

The JET-shear will reduce your in-tank mixing time by up to 70% compared to conventional mixers. Save time and money over tedious hand mixing methods.

JET-shear Advantages

Customizable

Efficient and consistent blending

304 Stainless Steel Adapter

Affordably Priced

Fast Delivery

Manufactured and Assembled in the U.S.A.

Available Models

| Standard Bearing Frame Sizes | Max Shaft Length | Standard Shaft Diameter | Workhead Diameter |

|---|---|---|---|

| JS125 | 48" | 1.25" | 2.5"-4.0" |

| JS150 | 60" | 1.50" | 3.5"-4.0" |

| JS200 | 84" | 2.00" | 3.5"-4.5" |

| JS225 | 84" | 2.25" | 4.5"-6.0" |

| JS300 | 96" | 3.00" | 5.0"-8.0" |

| JS400 | 96" | 4.00" | 6.0"-10.0" |