How The Right Mixing & Blending Processes Create Your Ideal Product

Blending and mixing processes are here to stay. The growth of dairy, chemical, and food reconstitution has forced product offerings to evolve into what they are today. If the customer isn’t reconstituting, they are probably adding ingredients or batching different recipes. Versatility and speed are the two most important factors that manufacturers have to address in the blending and mixing sector.

Problems arise when producers need to dump bags of dry ingredient into vessels. Potential danger arises when operators have to stand on elevated structures and physically lift the bags to the appropriate level. This is why inline blending and mixing gives producers the means to solve logistical and safety issues. In addition, bag dumping into a vessel does not guarantee adequate wetting and dispersion of dry ingredients. Once the dry ingredients are in the mix, the operators are relying on the in-tank mixing or agitation to blend the wet and dry ingredient. This is a limiting factor in almost all processes of this type. Often, this incorporation takes several hours, or even entire shifts, when combining bag-dump and wait-time. These reasons encompass why inline blending and mixing equipment offer advantages to product quality as well as process efficiency.

Continuous Processing

There are many varieties of equipment in blending and mixing. Continuous is an essential technique for plants trying to expand and improve. Because of this, equipment that does not limit manufacturing to batches or piece-wise intermittence is important to blending and mixing. The size of a continuous process is only limited by the producer’s time requirements. Continuous processes are also carried out with familiar equipment: pumps, shear blenders, eductors, and static mixers. Combining this equipment is where time savings really begins. Continuous processing is a balance of producer requirements, along with producer capabilities, and it is important for manufacturers to fit the needs of all size producers, from experimental to large scale.

Inline Induction

This is a popular method to induce dry or wet ingredients into a stream of fluid. There are many methods to achieve this, including:

1. Inducing dry or wet ingredients on the low- pressure side of a pump or shear blender by creating vacuum from velocity gradient or naturally from high flow — operating toward the upper limit of the pump’s flow capacity.

2. Induce dry or wet ingredients on the high- pressure side of a pump using cross-sectional area difference. This process uses an educator.

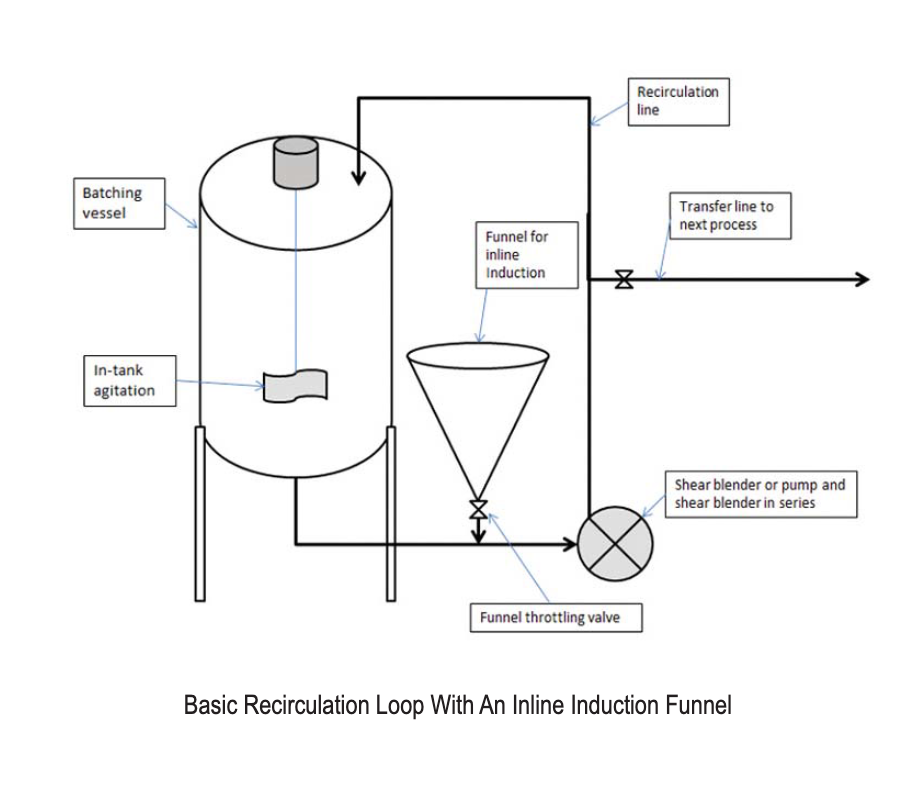

Both of these processes can be done once-through or with recirculation. A batch in its most-simple form has ingredient A and ingredient B. One of these is a liquid and one is a powder. Recirculation requires the liquid component to be continuously recirculated until all of the powder is induced.

Once the powder is induced, the process may be complete or more recirculation will be required to speed up incorporation and blending. This must be carefully planned so the producer is not dissatisfied with the overall time of the process. Once-through processes require tank transfers of the liquid ingredient from one tank to another where the powder is induced inline during transfer. Usually these processes finish with a higher concentration of powder-to-liquid than the finished product so that the producer can dilute the final mixture once it’s ready for the next process. Inline induction usually works well in pair with shear blending of the mixture. These two sub-processes coincide often because of their effectiveness when used together.

Inline induction has many benefits. It begins when the auxiliary ingredient is forced into the confined space of the process piping or tubing. Therefore, it all must be subjected to the pump or blender’s shear immediately after it is incorporated. This is especially important when the producer has large volumes in their batch. For example, 5000 gallons of product recirculated at 300 GPM will yield a 17 minute theoretical tank turnover. Depending on the agitation, inlet, and outlet port locations on the tank, all of the mixture might not be subjected to the recirculation pump, blender, or combination of both. Even if the entire contents of the tank are exposed to the recirculation pump or blender, once-through might not be enough and this is where the 17 minutes becomes a critical estimating tool for process time. Because of this, a manufacturer must carefully specify the right size equipment for the system as to ensure success regardless of whether the customer has 50 gallons or 50,000 gallons.

The most important step in the overall process is induction time. This is because that aspect of the process often requires at least one person as a bag dumper. The operator must pay close attention to the process to avoid errors and detect problems because errors may ruin the entire batch. It is always best for the manufacturer to convince the producers to attempt the process with as quick of an induction time as possible. The hopper, induction valve, and tubing will be smooth and streamline at the start of the process. Their smoothness is important because intermittent splashing will occur just below the valve. Moisture in the induction area causes dry ingredient to stick to the walls of the tubing and reduce the area. This is more of a problem with some ingredients over others, but it affects all processes. Because of this, the manufacturer should help the producer choose an induction time proportional to the overall time of the process. If the powder is highly soluble, sometimes the induction time is the entire process time.

Inline induction is not all about speed. The proportion of fluid to dry ingredient that the pump or blender is inducing must be carefully controlled. Too much dry ingredient and not enough wet ingredient can cause product quality issues. Shear blenders, used in tandem with induction equipment, need to mix the two components. If there is not enough of one of the components present, the potential for large particles to pass through is high. Many pumps can easily create enough vacuum when an inline valve is throttled to induce more than what should be for the process. Some dry ingredients also have incorporation limits based on their effects on the mixture. Thickeners must be induced slowly so their increase on the mixture’s viscosity doesn’t happen violently and stop process flow. In this case, their incorporation time should be maximized as much as possible since they are also some of the hardest mixtures to blend thoroughly.

Controlling Process Speed And Induction Rate

Monitoring and adjusting pumps and blenders accordingly on induction equipment are ways to control the process speed and induction rate. Sometimes the dry ingredients are reluctant to induction. Inline process problems often occur when a powder material clumps or bridges and will not feed down the funnel. There are many ways to combat this, such as pneumatic or electric vibrators, grates, screens or structures within the hopper, and screw feeders or ribbon augers. Sometimes, keeping the funnel semi-empty — the induction rate is higher than the infeed rate — is a solution as well. This is often not viable because this method induces air, as well as dry ingredient, which can adversely foam or damage the product.

Temperature also has an effect on inline induction. Higher temperatures aid in the solubility of dry ingredients into wet ingredients, but also adversely affects the vacuum created by the blender or pump. This is because the vapor pressure of the fluid increases as its temperature rises. For example, water at 150 F has about four psi more vapor pressure than water at 65 F. Higher temperature fluids also have the tendency to cause powders to nucleate and stick on the wall of the tubing or valve. Producers should find a balance of safety and speed when considering process temperature.

Shear Blending

High-shear blending is a process that subjects fluids or mixtures to high-velocity differentials inside a centrifugal blender by using static elements that purposely obstruct the flow.

The static elements (teeth on the cover that do not move) come within close clearances to dynamic elements (teeth on the impeller that spin) to create a proximity aspect to that velocity differential. Internal velocities in the shear blender are much greater than that of a typical centrifugal pump. These shear blenders reduce particle size with large particles — larger than the clearances between static and dynamic elements — or small particles — smaller than the clearance — alike. The principle of large- particle reduction is that the blender guarantees shearing of the particle because the velocity of the particle is much slower than the velocity differential of the multiple rows of static and dynamic teeth. The principle of small-particle reduction is that great amounts of turbulence aid in the particle’s incorporation into liquid, even though the particle may have opportunities not to be sheared by the static and dynamic elements.

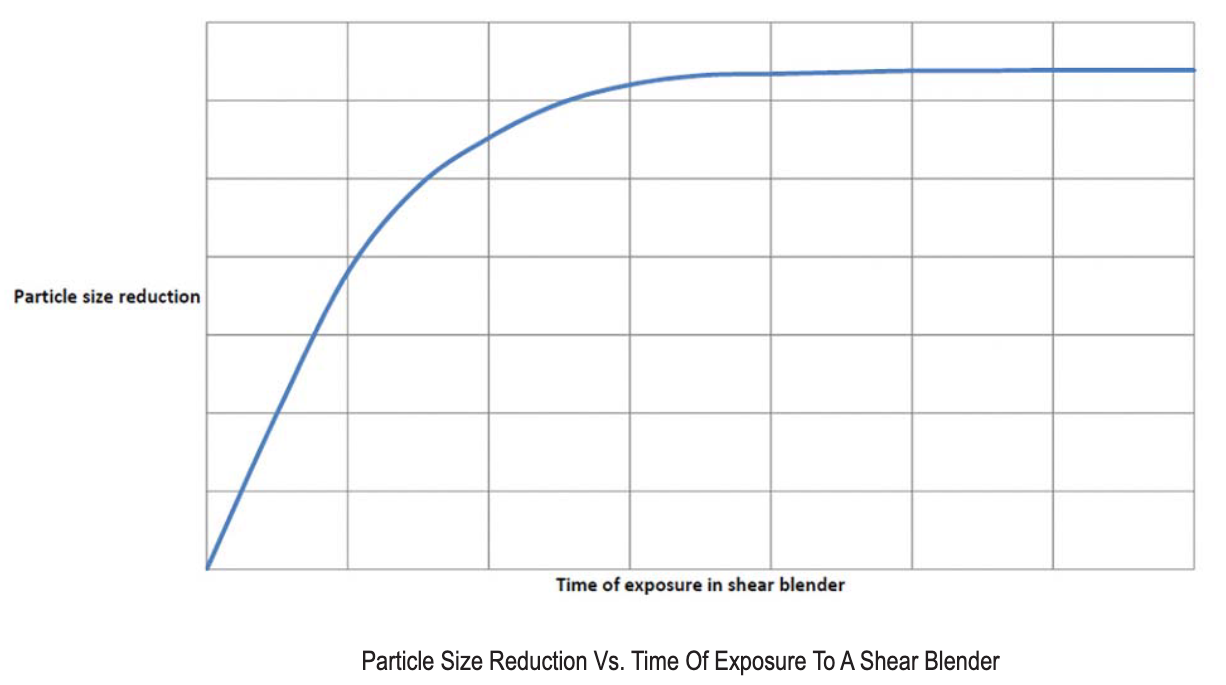

Many first hand reactions to this type of equipment show an occurrence where particles much larger than expected are allowed through the blender on the first pass. This is due to probability as there are always opportunities for particles to seemingly escape much larger than others. This is why recirculation through the shear blender is important to processes with strict particle size criteria. Each time particles pass through a shear blender they will see reduction in size. As they get smaller and approach the clearances in the blender, the size reductions become asymptotic. Recirculation as a means to reduce particle size also has limitations. Some product will aggregate back into its components after being exposed to shear blenders. These are sometimes referred to as “fish eyes.” This can be very adverse to the finished product, especially if consumers do not accept the product after visual inspection. Recirculation will not fix fish eyes. The product must be subjected to higher shear, either by larger equipment or more equipment in series. This higher initial exposure on the first pass has more shear magnitude, rather than longer dwell, similar to cutting grass shorter has more effect than cutting it twice with the same mower.

On the other side of the spectrum, some products need particle size reduction, but can be over-sheared. Many food products must fit within strict criteria, ultimately put in place by tradition or consumer response. Stews, soups, or sauces usually have criteria for particle size that is somewhere in the medium range. Polymeric fluids have organic chains that will never recover when sheared. Over-shearing polymers can spell trouble for the manufacturer as this changes the properties and effectiveness of the polymer. Shear blenders should have a large speed range and offer many different geometries to fulfill the needs of more sensitive products. The flow in which the blender is fed affects dwell, thus changes the particle size as well.

Shear blenders should be versatile in their applications. They should be able to handle viscosities less than 1 centipoise, up to tens of thousands of centipoise. When specifying centrifugal equipment, such as shear blenders, high viscosities affect the power requirements greatly.