Best in Class Pumps, Mixers and Blenders for the Dairy Industry

As the need for quality milk, cheese, whey and related by-products continue to grow in demand, dairy processing partners are looking to Ampco for more efficient and sanitary equipment – at a cost-effective price point.

Ampco is committed to offering a wide range of economically priced products to heed the call for sanitary dairy processing applications.

From centrifugal pumps and positive displacement pumps to Ampco’s customized solutions for mixing and blending, you’ll find a portfolio of versatile and durable products that can be delivered quickly.

Discover for yourself Ampco’s commitment to the Dairy Industry. Contact Ampco today.

At Ampco, we understand downtime means lost production and revenue. Let us be the partner to keep you up and running with pumps excelling in reliability, durability and performance.

Delivering Flexibility and High Efficiency

Best Selling Dairy Processing Products

ZP3 Series

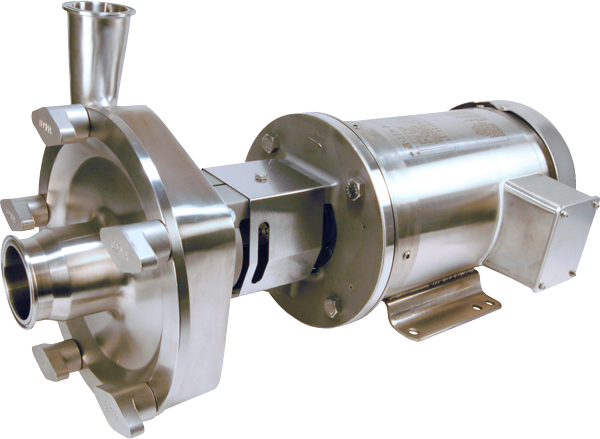

AC+ Series

L Series

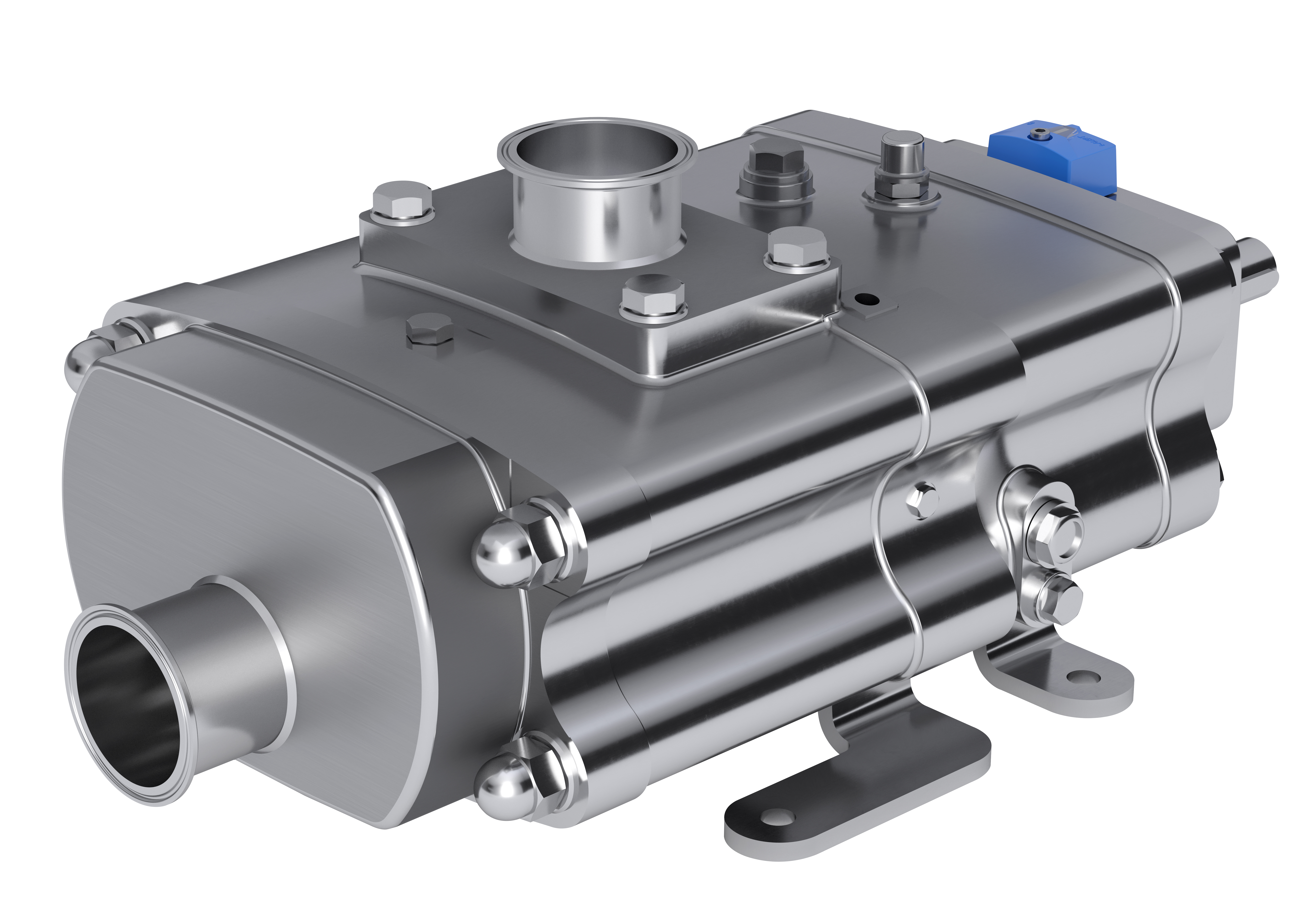

SLH Twin Screw Pump

Offering Bi-Directional Flow and Speeds up to 3,000 rpm to Allow Gentle Processing of Soft Solids and Viscous Products, and CIP in One Unit

SBI Series

Inline shear pump that is both a shear blender and a transfer pump, thanks to its hybrid impeller design.

Application Spotlight

SLH Excels in Product Integrity

The SLH Twin Screw pump is ideal for dairy applications, especially ice cream and yogurt. The SLH is capable of delicately processing soft solids to maintain density and visual integrity. Pumps are 3A and EHEDG Certified.

When performance and processing flexibility are paramount, the SLH is often the answer. Fully CIP-able and bi-directional, the SLH Twin Screw positive displacement pump provides low shear, is capable of handling viscosities up to 1,000,000 cP, and particulates sizes up to 1.5”/ 3.8 cm.

Committed to Food Safety

As producers look to increase product shelf life without decreasing the quality of their product, they look to Ampco. Ampco manufactures the highest quality sanitary pumps mixers and blenders with customer satisfaction first in mind. Products that are simple to maintain, built using quality materials, designed with sanitary requirements in mind and offering the best customer service in the industry.

Ampco offers dairy processing plants equipment that is reliable and affordable. Ampco manufactures products that are CIP-able (clean-in-place) for ease of maintenance. And, nearly every Ampco sanitary pump meets 3A Sanitary Standards or is EHEDG Certified. In several circumstances both certifications apply. Sanitary applications are taken seriously at Ampco. The fully-staffed Ampco R&D team is attuned to developing sanitary regulations and answering the need for new technologies.

Sanitary applications are taken seriously at Ampco. The fully-staffed Ampco R&D team is attuned to developing sanitary regulations and answering the need for new technologies.