K Series Reliable Durable Compact Design

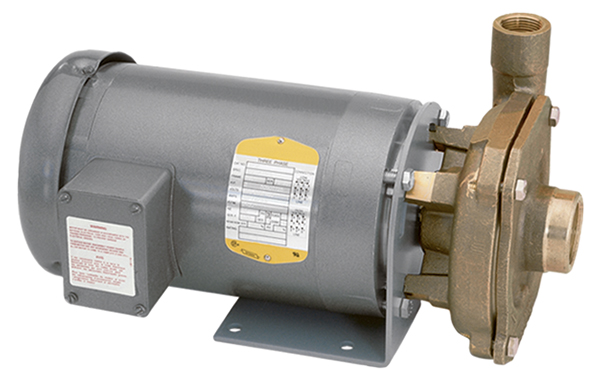

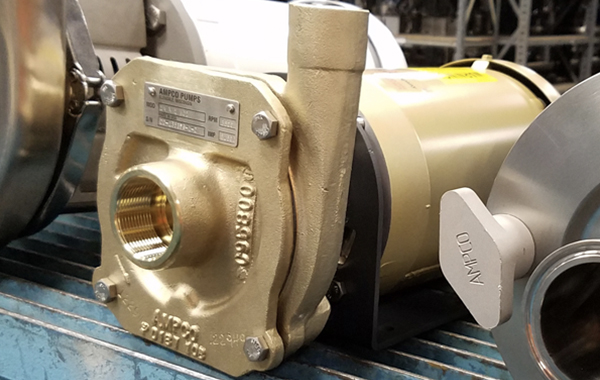

Ampco’s K Series line brings the same durability as the Z Series but in a smaller size. K Series high efficiency pumps have NPT threaded connections and are close-coupled to NEMA 56J frame motors. Available alloys include 316 stainless steel and nickel aluminum bronze.

Used heavily by the United States military in desalination systems, K Series pumps are installed worldwide. All K Series pumps have ABS (American Bureau of Shipping) type approval and are available for delivery in 1 week or less.

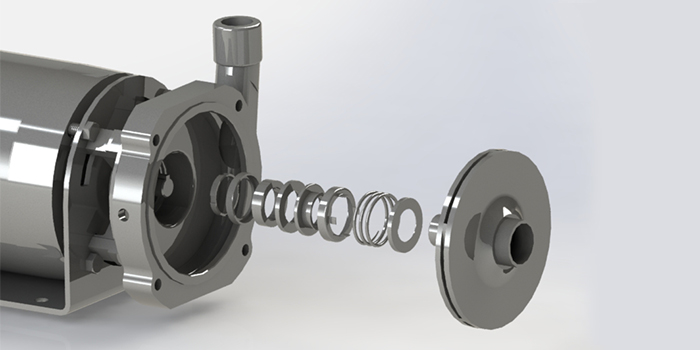

Features of the K Series include pressure capabilities as high as 150 PSI/ 10 BAR, temperatures ratings as high as 225°F/ 105°C, have multiple seal options, and replaceable wear rings.

The most common application for the K Series is reverse osmosis, yet this pump can be used in any number of corrosive and seawater applications including effluent wastewater and desalination processes.

K Series

Marine and Industrial Centrifugal Pump Features

- High Efficiency

- Multiple Alloys – 316 Stainless Steel, Nickel Aluminum Bronze

- Machined, Heavy Wall Construction

- Dynamically Balanced Impeller

- Multiple Commercial Seal Options Available

K Series Performance Overview

Models: 12

Max Discharge Pressure: 150 PSI / 10 BAR

Max Flow Rate: 230 GPM / 52 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 6 Seal Options

K Series Centrifugal Pump Advantages

- High Efficiency

- Heavy Wall Cast Construction

- Versatility of Multiple Alloy Construction

- Flush and Frame Options Available

- Enclosed Impeller

US orders: New pumps ship in 1-2 weeks, parts orders in 24 hours

International order transit times will vary based on destination- Manufactured and Assembled in the U.S.A.

Application Spotlight

Ampco has been supplying the United States military and Department of Defense contractors with durable and reliable pump technology since the 1940’s. In fact, the Ampco KC2 pump is used to boost pressure on a 1500 ROWPU reverse osmosis system built by Highland Engineering, Inc. These systems using Ampco pumps stand up to brutal conditions around the world.

Highland Engineering Inc.

Howell, Michigan

Available Models

| Model # | Curves | 1750 | 2900 | 3500 | Data Sheet |

|---|---|---|---|---|---|

| KC2 1 x 3/4 BRONZE | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 1 x 3/4 STAINLESS STEEL | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 1-1/4 X 1 | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 1-1/2 x 1 | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 1-1/2 x 1-1/4 BRONZE | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 1-1/2 x 1-1/4 STAINLESS STEEL | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 2 X 1-1/2 | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KC2 2-1/2 X 2 | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KP2 1 x 3/4 BRONZE | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KP2 1 x 3/4 STAINLESS STEEL | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KP2 1-1/4 X 1 | Curves | 1750 | 2900 | 3500 | Data Sheet |

| KP2 1-1/2 x 1 | Curves | 1750 | 2900 | 3500 | Data Sheet |