Big on Performance, the Metric LM Series Front Loading Seal is Maintenance Friendly

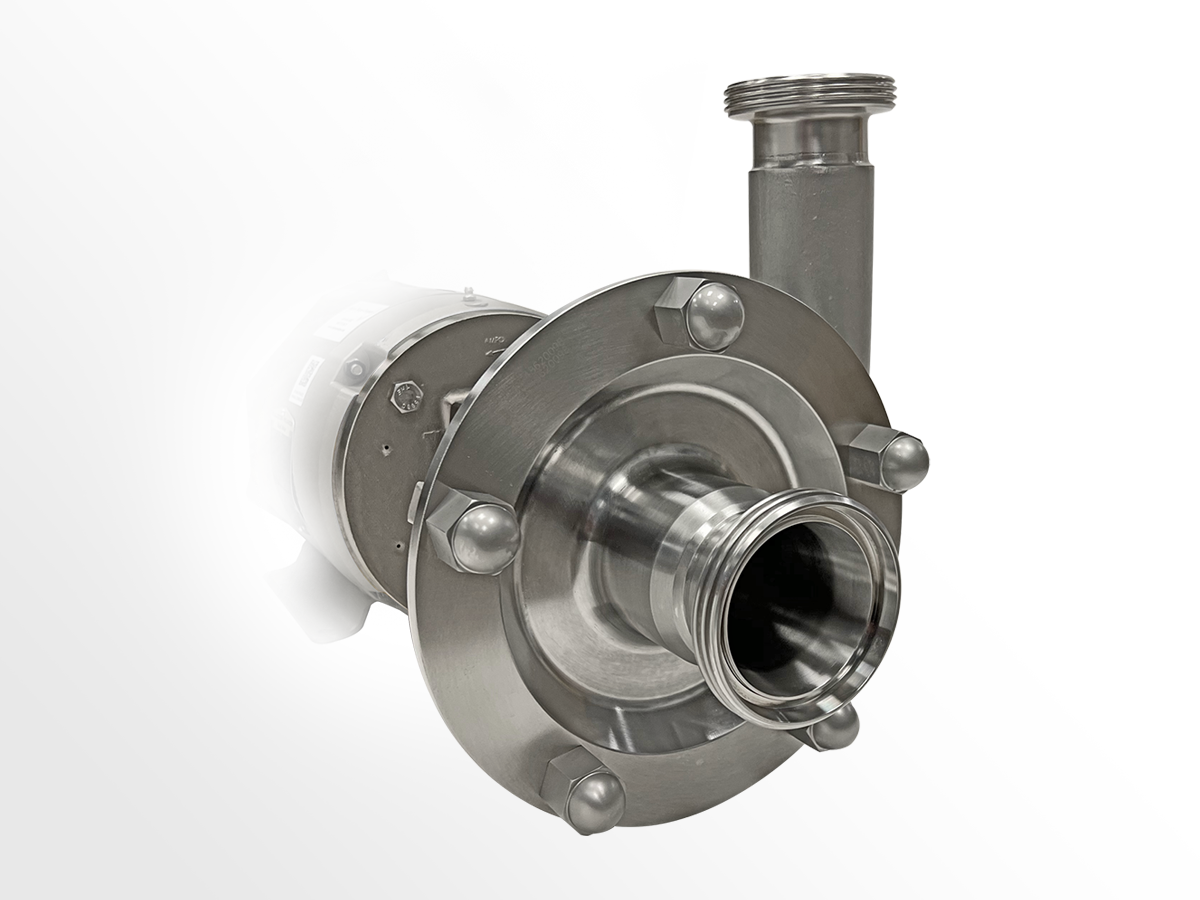

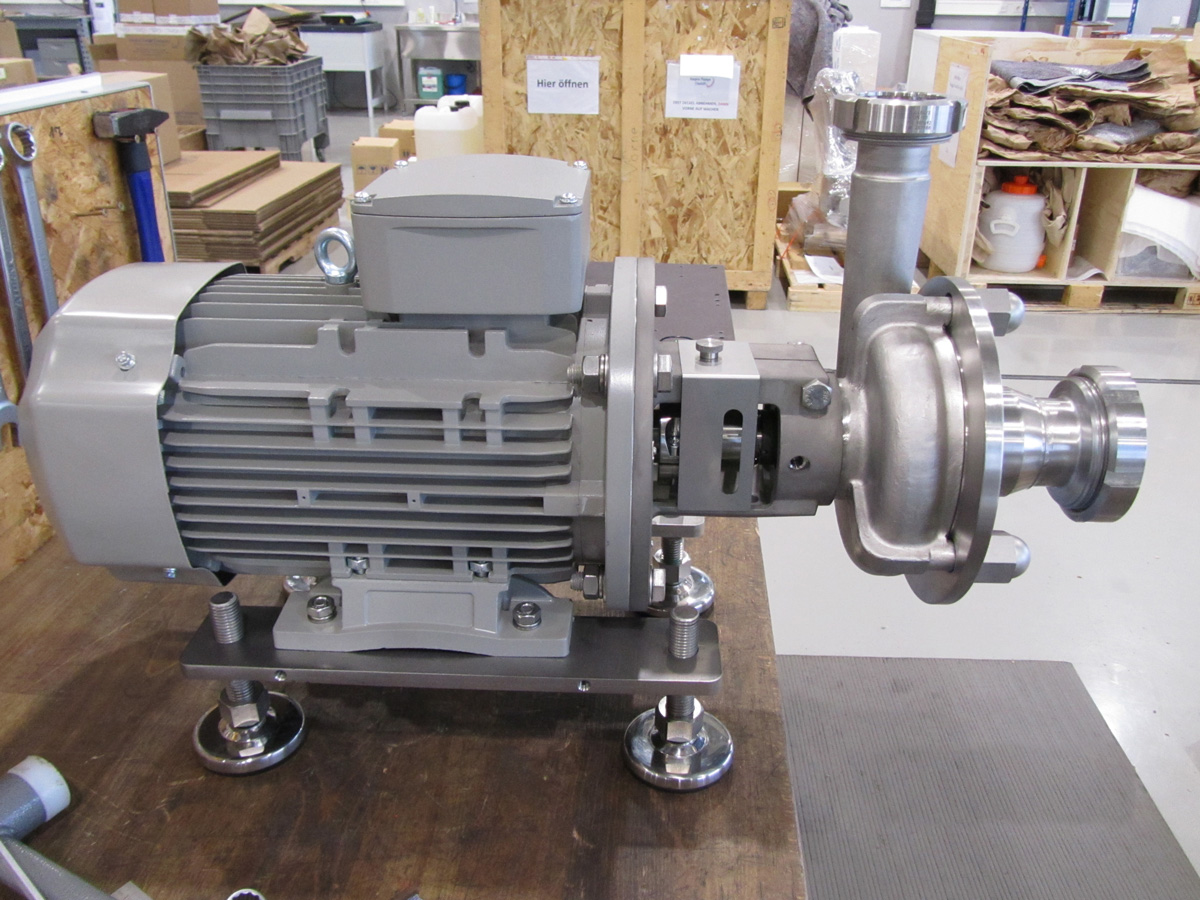

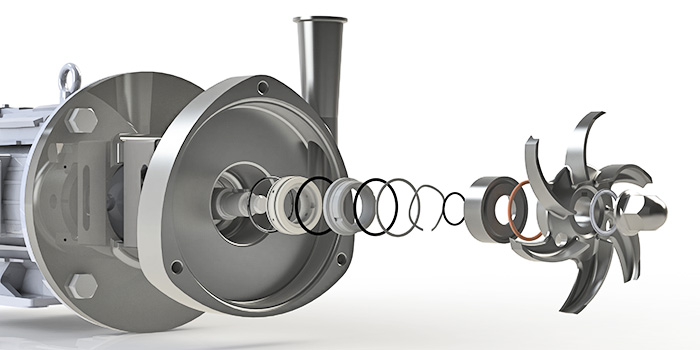

Ampco’s metric LM Series centrifugal pumps are designed with a unique front-loading seal similar to the LF Series US measurement version. The front-loading seal design excels at ease of maintenance and improved cleanability.

Seal designs in competitor pumps have been known to leak due to product build-up when processing sticky products, the Ampco front-loading seal design eliminates this problem by removing the O-ring groove and dead zone. The unique design of the Ampco LM seal offers a semi-exposed O-ring allowing the product to flow freely through those traditionally restricted areas solving the product build-up dilemma.

The Ampco LM, rotating seal stays in place inside the driver during the assembly process. This design also facilitates ease of assembly.

Balanced impellers, a self-aligning shaft design and tight tolerances in manufacturing minimize vibration and improve seal life, making the LM an excellent choice for difficult-to-handle products.

The LM Series is a highly efficient centrifugal pump that handles product gently while providing a more sanitary seal design than competing pumps.

Industry-leading delivery times, 304 stainless steel adaptors, seal design advantages, and a maintenance-friendly assembly process makes Ampco’s LM Series the right choice.

Cryogenic Low Temp Applications. CBD hemp oil or Cannabidiol is fast becoming a mainstream ingredient for beverages, health products, gels, and other consumables products. The extraction process of these valuable oils can require pumping ethanol at temperatures as low as -70F (-56C). Ampco has designed a special seal for positive displacement and centrifugal pumps that are suitable for these extremely low temperatures.

The LM Series centrifugal pump series with its internal seal design is a smart choice for this application providing durability, efficiency and tremendous maintenance advantages, contact Ampco’s Technical Sales Team today to discuss your specific application requirements.

Ampco Pumps Cryo-pump Technology – Learn More

The front loading seal can be changed simply by removing the front cover and impeller.

LM Series

Centrifugal Pump Features

- 316L Stainless Steel Heavy Wall Construction

- Cast and Machined

- 304 Stainless Steel Adapter

- Balanced Impellers

- 316L Stainless Steel Shaft

LM Series Performance Overview

Models: 13

Max Inlet Pressure: 10 BAR

Max Flow Rate: 409 Mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 3 Seal Options

Proven Design & Upgraded Features

The LM Series gives end users the added benefit of a cleaner seal design with partially exposed O-rings making it easier to handle seal assembly. The result – reduced downtime resulting in greater profitability.

LM Series Centrifugal Pump Advantages

- 304 Stainless Steel Adapter

Cleaner Seal Design

Rotating Seal Retained for Ease of Assembly

Convert to Double Seal Easily in the Field

US orders: New pumps ship in 2-3 weeks, parts orders in 24 hours

International order transit times will vary based on destination

Front-loading seal design is simple to maintain and easily changed to a double mechanical seal

Available Models

| Model # | Data Sheet and Curves |

|---|---|

| LM R01/R02 | LM R01/R02 Data Sheet and Curves |

| LM R11/R12 | LM R11/R12 Data Sheet and Curves |

| LM R21/R22 | LM R21/R22 Data Sheet and Curves |

| LM R31 | LM R31 Data Sheet and Curves |

| LM R41/R42 | LM R41/R42 Data Sheet and Curves |

| LM R141/R142 | LM R141/R142 Data Sheet and Curves |

| LM V521/V522 | LM V521/V522 Data Sheet and Curves |

| LM V531/V532 | LM V531/V532 Data Sheet and Curves |

| LM V541/V542 | LM V541/V542 Data Sheet and Curves |

| LM V551/V552 | LM V551/V552 Data Sheet and Curves |

| LM X051 | LM X051 Data Sheet and Curves |

| LM X161 | LM X161 Data Sheet and Curves |