Excellence in Food and Beverage is Achieved in the Details

The Food and Beverage Industry is one of the most rapidly evolving industries. Changes in government regulations, consumer preferences for healthier options, food quality and safety demand constant flexibility from food and beverage processors.

Today, consumers are becoming more discerning about both the origin of their food and the safety of the ingredients. Some companies are already removing or replacing artificial ingredients in their products with more natural alternatives. While transparency in labeling continues to be under the microscope, the food and beverage industry is experiencing transformational changes in consumer preference.

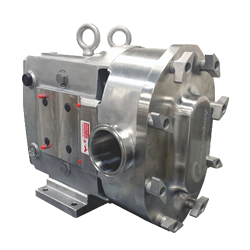

With safety in food processing of vital importance, having quality, corrosion-resistant, reliable equipment is essential for feeding a global population. Ampco has focused on engineering excellence and incorporated innovations such as front loading seal technology on the patented ZP3 to reduce down time and increase efficiency. You can feel confident choosing an Ampco pump… it will serve as the ultimate pump for reliability.

Delivering Quality and Efficiency

ZP3

ZP1

>> View more

LF Series

AC+ Series

>> View more

Ampco’s Commitment to the Food and Beverage Industry

All foods are not created equal when it comes to processing. From variations in viscosities to processing hot oils, challenges in processing cocoa, chocolate and gum-like substances and beyond. Ampco’s pumps, mixers and blenders need versatility, reliability and durability to meet the needs of demanding sanitary food processing applications. Ampco meets that challenge head on – with solutions on the ready and a full R&D staff to address new food and beverage processing opportunities.

For over a decade, Ampco has honed its product offerings for the food and beverage industry. Ampco offers a variety of pumps for sanitary applications from positive displacement pumps to centrifugal pumps serving a wide range of viscosities, pressures, flow rates and mechanical efficiencies.

Plus, Ampco’s Applied Products Division delivers high performance, high efficiency products – powder mixers, powder inducers, dry blenders, shear blenders and shear pumps — to best serve the needs of its food and beverage partners. In mixing and blending applications, product customization is vital to achieving the right outcome and batch consistency. Ampco has a dedicated R&D department staffed with seasoned engineers to work with customers on the nuances needed to accomplish their processing specifications.

Application Spotlight

Chocolate Manufacturer, East Coast U.S.A.

“After struggling for years with o-ring seals that lasted only days, we were introduced to the Ampco ZP1 Series positive displacement pump with a triple lip seal for the application. The new pump and seal is lasting substantially longer than the competitors’ previous technology, we are thrilled with the production capabilities Ampco Pumps offers.”

Certifications:

3A & EHEDG Certified

- QTS

- ZP3 (what about the rest of the ZP Series??)

- L Series (all of the L Series – LC, LD, LF, etc. or only some?)

3A Certified Only

- AC Series

- M Series