POWDER-max Delivers Efficient, Precise Mixing

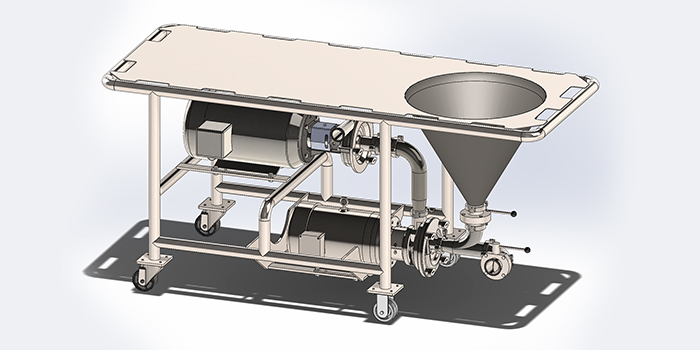

Ampco’s Applied Products POWDER-max reduces processing time and provides optimal product consistency with no batch size limitations. An innovative design allows PM Powder Mixers to quickly blend wet and dry ingredients in a single, fully portable unit.

The POWDER-max combines Ampco’s SP Series liquid ring pump and the SBH Shear Blender in-line to facilitate limitless production runs.

Five standard models are available and the POWDER-max can be customized for a multitude of processing requirements.

The even flow of liquid created by Ampco’s self-priming SP liquid ring pump, ensures product is mixed consistently from batch to batch. The SBH Shear Blender, runs at high speeds to continuously mix the fluid and powder providing a superior end product.

The POWDER-max is CIP-able, and is designed and assembled with clean-ability being at the forefront.

Trials, rental and leasing options are available. More info Contact the AAP team today to discuss your specific blending needs.

In-house welding, polishing and assembly departments ensure a seamless production process… and make it possible for Ampco to offer the best delivery times in the industry.

POWDER-max Features

- Model SP Liquid Ring Pump

- Model SBH Shear Blender

- 304 Stainless Steel Base Material

- 316L Wetted Parts

- Dual Motor Starter – NEMA 4X

- Stainless Steel Casters

- Powder Control Valve

- Fluid Control Valve

POWDER-max Performance Overview

Models: 5

Max Flow Rate: 210 GPM / 48 Mᵌ/hr

Max Powder Induction Rate: 300 lbs/min / 136 kg/min

Hopper Capacity: 3.4 ftᵌ / .10 mᵌ

Seal Specifications: 2 Seal Options

Pumps in Action

“It’s the best money we’ve ever spent!”

Cheese Manufacturer,

Western United States

POWDER-max Advantages

- Clean-In-Place (CIP-able)

- Completely Sanitary Design

- Customizable – Optional Features Available

- Welded Hopper

- Trials Available

- Rentals Available

- Affordably Priced

- Four Week Delivery

- Manufactured and Assembled in the U.S.A.