High Shear Inline Mixing with a Twist

The ultimate in high shear mixing and dispersing, meeting the tight tolerances required in high shear applications while maintaining extremely efficient flow.

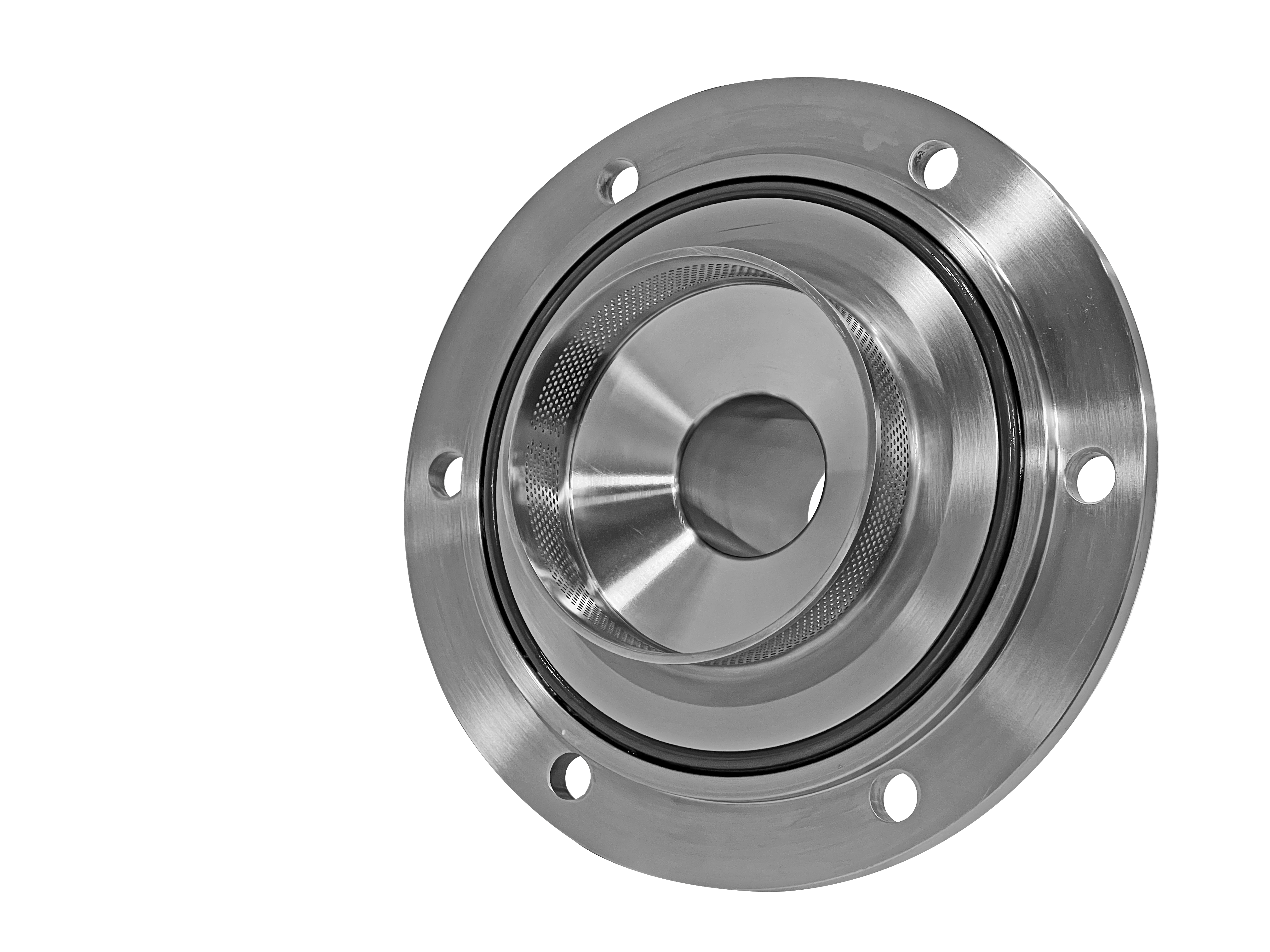

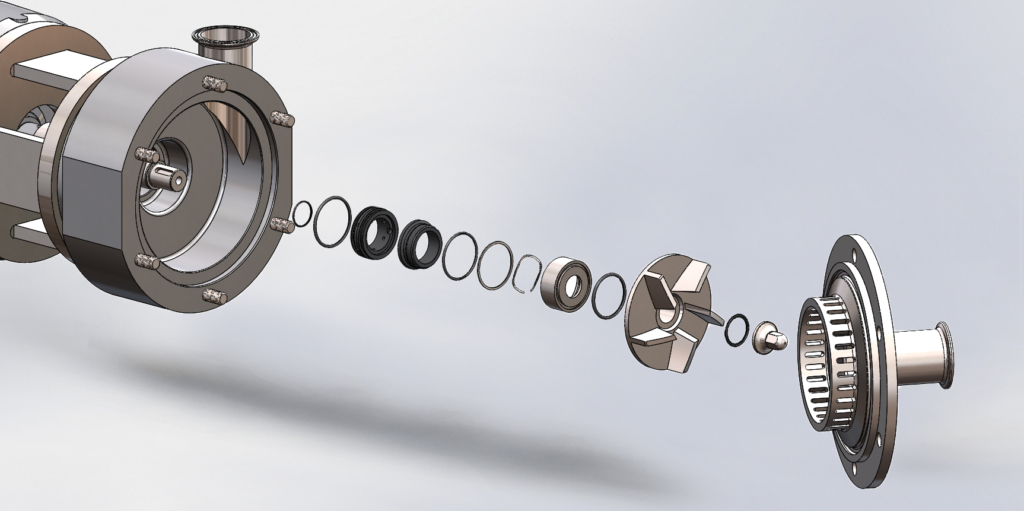

The curved wedge rotor and stator design of the SHEAR-max make it one of the most efficient and hygienic designs on the market. The SHEAR-max will disperse, dissolve, emulsify, de-agglomerate, homogenize, or simply blend.

Designed for single pass or batch style processing of liquids and semi-solids this high shear mixer is extremely effective at hydrating and dispersing powders. The innovative wedge style rotor allows solids into the shear zone while efficiently employing motor horsepower. The single or dual stage stator provides superior clean-ability and tight rotor / stator tolerances.

Machined from 316L stainless steel bar stock this mixer is built to last. Wash-down and CIP capability with optional chemical duty designs available.

Trials, rentals and leasing options are available. More info

SHEAR-max Features

- High Shear Mixing

- Single and Dual Stage Options

- Pump and Blend in a Single Stage

- Machined from 316L bar stock

- 304 Stainless Steel Adapter

- Dynamically Balanced Impeller

- 316L Stainless Steel Shaft

SHEAR-max Performance Overview

Models: 7

Max Flow Rate: 800 GPM / 182 Mᵌ/hr

Seal Specifications: 3 Seal Options

SHEAR-max Advantages

Front Loading Seal Options

304 Stainless Steel Adapter

Affordably Priced

Two Week Delivery

Manufactured and Assembled in the U.S.A.

Need quick delivery?

Ampco’s standard delivery timing is unmatched – only 2 weeks. Call today!

Available Models

| Model # | Curves | Data Sheet |

|---|---|---|

| SM1300 | - | Data Sheet |

| SM1437 | - | Data Sheet |

| SM1575 | - | Contact us for information |