Z Series Corrosion Resistant Durable High Flow Pumps

The Z Series high efficiency centrifugal pumps shine in applications where corrosion resistance is of the utmost importance.

With an enormous worldwide installed base in countless industries, applications range from the shipping industry and effluent waste water instances to desalinization and reverse osmosis systems.

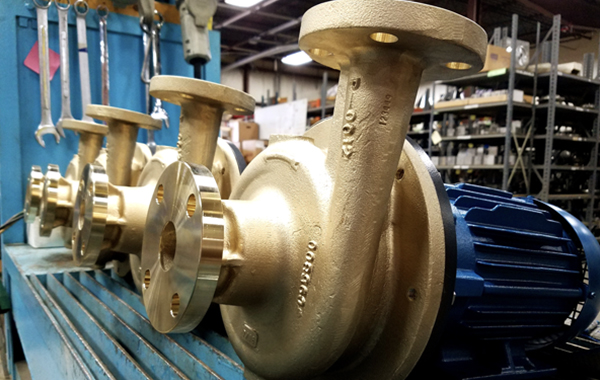

The Z Series pump line has been manufactured and assembled in Milwaukee, WI since 1948. Since its inception, the Z Series has been offered in 3 standard alloys – duplex 2205, 316 stainless steel and nickel aluminum bronze – and all providing superior corrosion resistance.

Specialty alloys are also available, including: Hastalloy C, Alloy 20 and 316L stainless steel. All Z Series pumps have ABS (American Bureau of Shipping) type approval and are available for delivery in as little as 1 week.

All Z Series pumps are close-coupled to NEMA or IEC motors. Ampco application engineers are available to help determine the correct alloy for your particular application. Call today for more information.

Features of the Z Series include pressure capabilities as high as 175 PSI/ 12 BAR, temperatures ratings as high as 250°F/ 120°C, high flow rates, and replaceable wear rings.

Z Series

Marine and Industrial Centrifugal Pump Features

- High Efficiency

- Standard Alloys – 316 Stainless Steel, Nickel Aluminum Bronze, Duplex 2205,

- Special Order Alloys – 316L stainless steel, Hastalloy C, Alloy 20

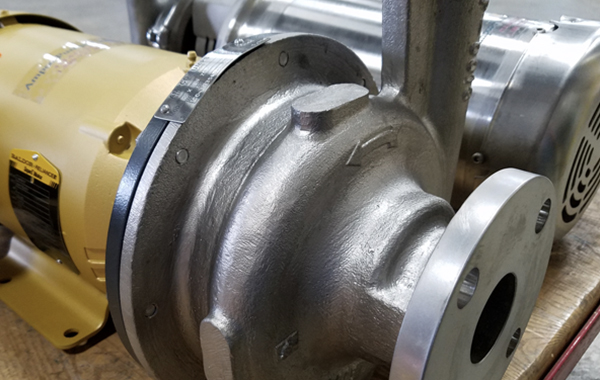

- Machined, Heavy Wall Construction

- Close-Coupled on JM, 56J, or IEC Frame Motors

- Fitting Options – 150# Flange, Cam and Groove, DIN Flange, JIS Flange

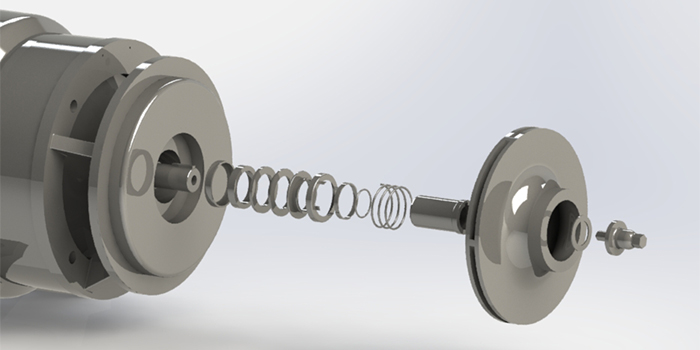

- Single Seal Options – Type 21 (Standard), Type 1, Type 9, with choice of seal materials

- Replaceable Wear Rings

- ABS Type Approval

Z Series Performance Overview

Models: 16

Max Discharge Pressure: 175 PSI / 12 BAR

Max Flow Rate: 3450 GPM / 784 Mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 6 Seal Options

Z Series Centrifugal Pump Advantages

- High Flow Rates

- Heavy Wall Cast Construction

- Versatility of Multiple Alloy Construction

- Flush and Frame Options Available

US orders: New pumps ship in 1-2 weeks, parts orders in 24 hours

International order transit times will vary based on destination- Manufactured and Assembled in the U.S.A.

Pumps in Action

Currently in operation on vessels across the globe, the Z Series line of pumps are installed for engine and condenser cooling, refrigeration, and reverse osmosis systems. Ampco engineers are available to assist in recommending the proper alloy for your application.

Available Models

| Model # | Curves | 1150 | 1450 | 1750 | 2900 | 3500 | Data Sheet |

|---|---|---|---|---|---|---|---|

| ZC2 1-1/2 x 1-1/4 Bronze | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2 1-1/2 x 1-1/4 Stainless Steel | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 1-1/2 x 1-1/2 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2 2 X 1-1/2 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 2 X 2 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2 2 1/2 X 2 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 3 X 2 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 3 X 2-1/2 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 4 X 3 | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 4 X 3C | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZC2/ZCH2 4 X 3L | Curves | 1150 | 1450 | 1750 | - | - | Data Sheet |

| ZC2/ZCH2 5 X 4P | Curves | - | - | 1750 | 2900 | 3500 | Data Sheet |

| ZCH2 6 X 6 | Curves | 1150 | 1450 | 1750 | - | - | Data Sheet |

| ZCH2 8 X 6 | Curves | 1150 | 1450 | 1750 | - | - | Data Sheet |

| ZCH2 8 X 6 M | Curves | - | 1450 | 1750 | - | - | Data Sheet |